Product information

- Catalogs and Download

- Product data, catalogs, and instruction manuals can be downloaded from the member site.

※ Membership registration is required.

Discharge capacity range (50/60Hz): 0.0033 - 5.0 L/min High-precision control in larger sized IX Series metering pumps

※In order to download information materials and catalogues, you need to register a user

account (for free) with us. Membership Registration

Max. capacity range: 0.2 – 300 L/H, Max. pressure: 1.0 MPa covers wide flow range.

The valve design maintains precise dosing at any flow rate whilst the motor regulates discharge and suction speeds to achieve high accuracy (+/-1%) all with a cost-effective design from a mechanically driven diaphragm pump.*

*Some low flow rate areas are excluded.

Fast priming without air locks is achieved with a high compression ratio due to a fixed (maximum) stroke length.

Standard IX series is capable of pumping liquid viscosities of up to 300 mPa•s.*

*Contact us for higher viscosity applications. When transferring viscous liquid, the discharge rate may decrease. Custom orders are also available for viscosities of 1000 mPa•s and above. Please contact us for details.

Drive and control units are sealed separately to an IP65 enclosure.

One of the IX features is multi-voltage operation (100 – 240 VAC) compatible worldwide. Compliant to UL, CE standards.

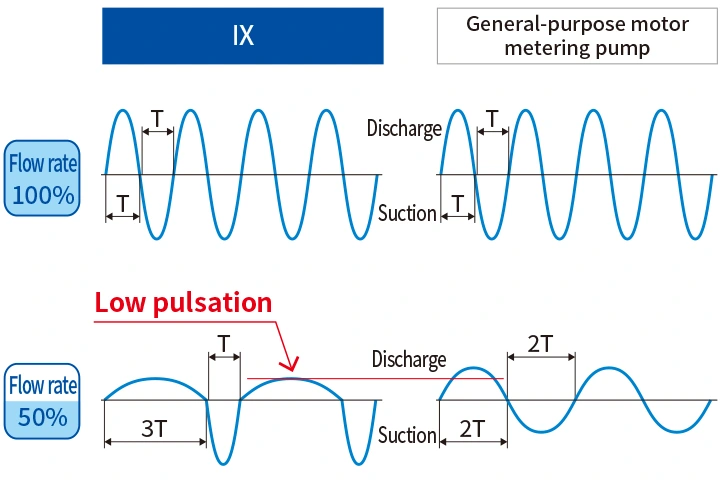

Flow control via discharge speed adjustment (with a fixed suction speed) assures constant injection at any flow rate. This system also reduces impact (inertia force) and load to the discharge line.

When pumping viscous liquids, suction stroke speed can be varied to avoid developing cavitation. (Programmable suction speed: 75%, 50% or 25% of the normal speed)

Keypad operation or the contact signal (AUX) runs the pump at maximum spm in any mode for degassing.

The pump is calibrated prior to shipment, however we recommend recalibration when installed in your system due to pipe layout and liquid properties.

Controller memory logs the total power connection time, operating time, number of strokes and number of power-up events.

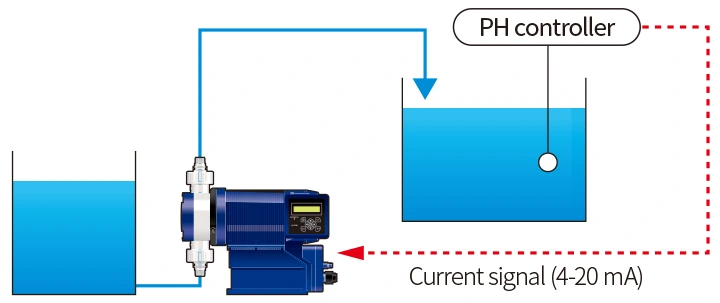

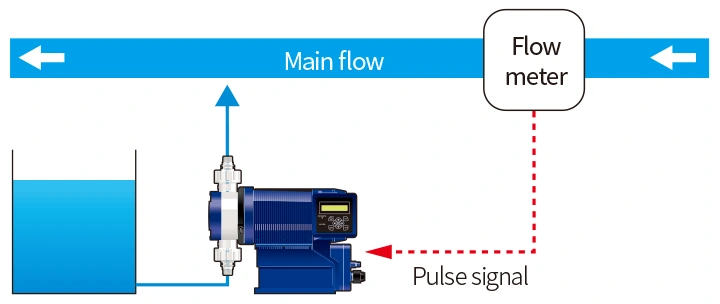

The IX can run in analogue, pulse, batch or interval batch modes.

The pump operates in response to an input, (4 – 20 mA) from a controller.

When combined with a flow meter or contact head water meter, the IX pump gives a paced dose rate in proportion to the main flow rate.

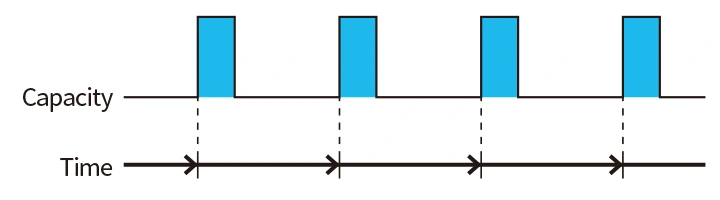

Timed operation is possible with simple pump programming via the keypad and is initiated with a pulse signal.

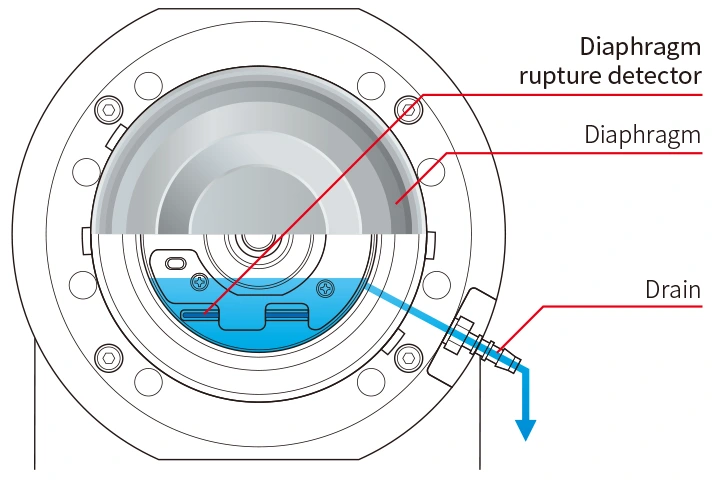

Standard to all models is a diaphragm rupture detector, protecting users and the environment. Also, a detector for abnormal operation protects the pipework in case of an accidental high discharge pressure caused by clogging or improper operation. A drain hole also ensures safe operation even when the diaphragm is damaged.

The controller position can be selected from 6 mounting positions for operator convenience. Also, a character LCD with LED backlight and optimized keypad positions assist easy operation.

| Max. discharge capacity range | 0.2 – 300 L/hr |

|---|---|

| Max. discharge pressure range | 0.5 – 1.0 MPa |

| Main materials | PVDF, SUS316 |

| Power consumption | 110 W |

| Liquid temperature range | PVDF type: 0 – 50°C SUS316 type: 0 – 80°C |

| Power voltage | 100 – 240 VAC 50/60Hz |

| Operation mode | MAN (Manual) | Use the UP and DOWN keys to set a flow rate. | |

|---|---|---|---|

| EXT | Analog fixed operation | 4 – 20, 0 – 20, 20 – 4, 20 – 0 mA (Proportional to the discharge rate) | |

| Analog variable operation | Programmable 2-point setting (Input signal DC 0 – 20 mA, proportional to the discharge rate) | ||

| Pulse control Note 1 |

D150: 0.01560 mL/PLS – 300 mL/PLS D300: 0.03120 mL/PLS – 600 mL/PLS |

||

| Batch control Note 1 |

D150: 15.6 mL/PLS – 300 L/PLS D300: 31.2 mL/PLS – 600 L/PLS |

||

| Interval batchcontrol Note 1 |

Day: 0 – 9, Hour: 0 – 23, Minute: 1 – 59 | ||

| Capacity D150: 15.6 mL/PLS – 300 L/PLS D300: 31.2 mL/PLS – 600 L/PLS |

|||

| Profibus controlNote 2 | Communication protocol: Profibus-DP-compliant international standard: EN50170 (IEC61158) | ||

| Input | STOP / Pre-STOP / AUX / Interlock | No-voltage contact or open collectorNote 3 | |

| Analogue | 0 – 20 mADC (Internal resistance is 200Ω.) | ||

| Pulse | No-voltage contact or open collector Max pulse frequency is 100 Hz. | ||

| Output | Alarm 1 (OUT1) |

Non-voltage contact (mechanical relay): AC 250 V, 3 A (resistive load)Each output item is selected by Enable/Disable. Batch completeNote 3/STOP/Pre-Stop/Interlock/Leak Detection/Motor Overload/Drive Error |

|

| Alarm 2 (OUT2) |

Non-voltage contact (photo relay): AC/DC 24 V, 0.1 A (resistive load)Each output item is selected by Enable/Disable. Volume Prop. PLSNote 5/Batch completeNote 4/STOP/Pre-Stop/Interlock/Leak Detection/Motor Overload/Drive Error |

||

| External power supply | DC 12 V, 30 mA or less | ||

| Current | DC 0 – 20 mA, Two-point setting (allowable load resistance: 300 Ω) | ||

Note1 : The minimum settings for pulse operation, batch operation, and interval batch operation are the flow rates per stroke corrected by calibration.

Also, the change rate of the setting value per pulse is the flow rates per stroke corrected by calibration.

Note2 : A separate Profibus conversion BOX (option) is required to operate Profibus on IX.

Note3 : The maximum voltage and current applied to the contact are 12 V and 5 mA. If you use a contact such as a relay, the minimum applicable load must be 5 mA or less.

Note4 : When Batch Complete (batch operation complete output) is set to Enable, the other functions will be set to Disable.

Note5 : When Volume Prop. PLS output is set to Enable, the other functions will be set to Disable.

Kindly use this inquiry form for placing an order or sending your inquiry

about our fluid control devices including chemical pumps.

HomeP