Product information

- Catalogs and Download

- Product data, catalogs, and instruction manuals can be downloaded from the member site.

※ Membership registration is required.

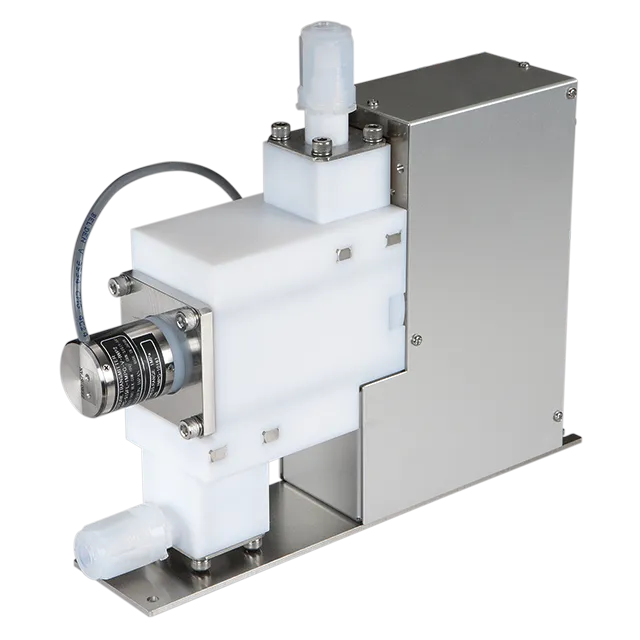

Max. discharge capacity: 12.0 mL/shot Capable of dispensing highly-viscous photoresist in LED or MEMS manufacturing

※In order to download information materials and catalogues, you need to register a user

account (for free) with us. Membership Registration

The use of a high-torque stepper motor as the drive source results in a consistent discharge volume, unimpeded by filter clogging or viscosity change. A repeatable accuracy (0.3%) of discharge is maintained.

• Discharge precision: ±0.3% (F.S.)

• Resolution: 0.01 mL

Since the discharge velocity can be changed freely in a shot, the system is capable of dealing with a variety of resist coating processes including application of a very small amount or in a very short period of time.

A discharge amount and a discharge time can be set only by entering values in the controller. It can save operator’s time and labor and reduce downtime.

Rated for viscosities up to 10,000 mPa·s used in manufacturing processes including LED and MEMS. And also for filling electrolysis solution.

| Max. discharge capacity | 12.0 mL/shot |

|---|---|

| Discharge speed | 0.5 – 2.0 mL/sec |

| Suction speed | 0.3 – 2.0 mL/sec |

| Max. discharge pressure | 1.0 MPa |

| Discharge precision | ±0.3% (F.S.) |

| Main materials | PTFE |

| Max. liquid viscosity | 10,000 mPa·s |

• Above specification may changed by installation, handling liquid, etc. For detail, please contact us.

Kindly use this inquiry form for placing an order or sending your inquiry

about our fluid control devices including chemical pumps.

HomeP