Product information

- Catalogs and Download

- Product data, catalogs, and instruction manuals can be downloaded from the member site.

※ Membership registration is required.

Discharge capacity range: 30 – 110 mL/min The optimum for gaseous liquid feeding

※In order to download information materials and catalogues, you need to register a user

account (for free) with us. Membership Registration

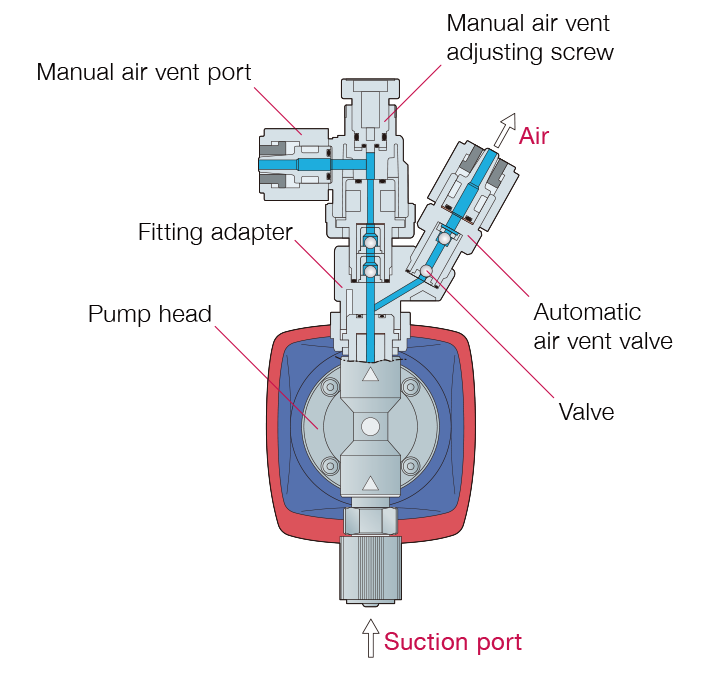

An air vent valve builtin pump chamber enables reliable air venting. The pump immediately resumes operation without gas lock even after a long period of stoppage. Also equipped manual air vent valve enables easy pressure release in discharge piping. Gaseous liquid such as sodium hypochlorite or hydrogen peroxide can be injected without gas locking.

The stroke rate can be set with 1 spm increments in between 1 and 360 spm. The stroke length adjustment further assists fine adjustment that the stroke rate adjustment cannot reach. Contentious precise chemical feeding is now available.

The use of the multi voltage circuit design allows the pump to work anywhere in the world.

The use of the integrated controller reduces a sealing area, so that the water-/dust-proof design of IP65 is attained. Also, a plastic cover protects the control panel under an adverse environment.

| Discharge capacity range | 30 – 110 mL/min |

|---|---|

| Max. discharge pressure range | 0.7 – 1.0 MPa |

| Main materials | PVC, PTFE |

| Stroke rate | 1 – 360 spm |

| Power voltage | 100 – 240 VAC 50/60 Hz |

| Liquid temperature range | -10 – 40°C |

| Viscous liquid | Please contact us for details. |

| Operational mode | MAN | 0.1 – 100% stroke rate | |

|---|---|---|---|

| EXT | DIV (Dividing) | /1 – 9999 | |

| MULT (Multiply) | ×1 – 9999 | ||

| ANA.R (Analog, rigid) | 4 – 20, 0 – 20, 20 – 4, 20 – 0 mA | ||

| ANA.V (Analog, variable) | 2 points 0.0 – 20.0 mA range 0.0 – 100% stroke rate | ||

| Control function | STOP/Pre-Stop | Pump keeps running when Pre-STOP is activated. Pump stops when STOP is activated. | |

| Prime | Pump runs at max. stroke rate while up and down keys are pushed. | ||

| Key lock | Key can be locked and unlocked. | ||

| Calibration | Discharge capacity per shot is calculated automatically by operating and stopping pump at calibration mode to make flow rate indication possible. | ||

| Buffer memory | ON or OFF is selectable. Max. 65535 stroke pulses are put in memory. | ||

| Input | Pulse | Non Voltage contact or open collector, Max. 200 Hz | |

| Current | DC 0 – 20 mA (Input resistance 200 Ω) | ||

| Level sensor | No Voltage contact or open collector, 2-steps contact | ||

| AUX | Pump runs at max.stroke rate while AUX signal is input. | ||

| Output | Photo-MOS relay AC/DC 24 V 0.1 A | ||

| STOP, Synchronous with stroke | |||

| Synchronous with stroke is standard. | |||

| Power Voltage | 100 – 240 VAC 50/60 Hz (90 – 264 VAC) | ||

Kindly use this inquiry form for placing an order or sending your inquiry

about our fluid control devices including chemical pumps.

HomeP