Product information

- Catalogs and Download

- Product data, catalogs, and instruction manuals can be downloaded from the member site.

※ Membership registration is required.

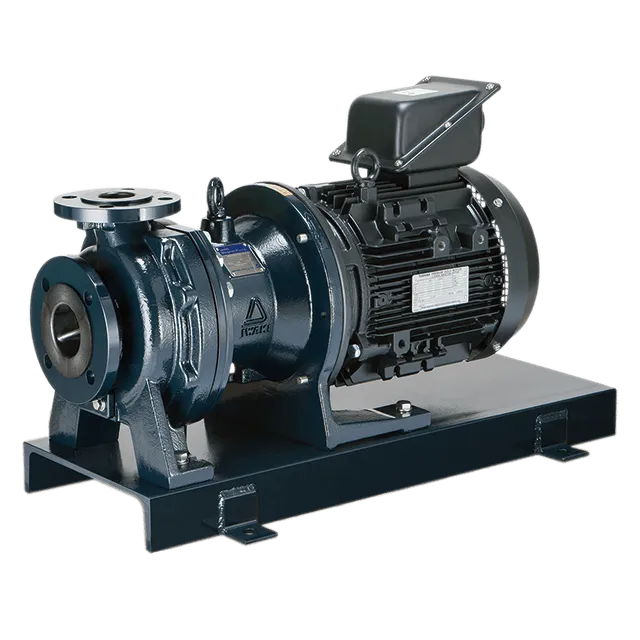

Max. discharge capacity range (50/60Hz): 400 – 1400 / 500 – 1400 L/min Polypropylene magnetic drive process pumps that strength against abnormal operation

※In order to download information materials and catalogues, you need to register a user

account (for free) with us. Membership Registration

A ductile cast iron shell adds strength and durability to the polypropylene wet ends. The rear casing, which is subject to the highest stress, is reinforced with an FRP cover to increase strength. The maximum allowable casing pressure of 1.0MPa is a highlight feature amongst polypropylene pumps.

The Back pullout system features a safety-first design that keeps the chemical sealed within the pump unit, even when the bracket is pulled back for maintenance. This system allows easy maintenance and inspection without removing piping. (Pump on baseplate only)

The AMP series features the Non contact system. The pump exhibits outstanding durability in air ingress to the suction.

• Dry running is not permitted.

The AMP series features a mechanism to withstand abnormal operation. High magnet power of the rare earth magnets prevents the magnet capsule coming into contact with the rear thrust, thus preventing melting of components due to heat generation. This greatly improves resistance against abnormal operation in comparison with conventional magnetic drive pumps.

The pump is a modular design for ease of maintenance. Specific adjustments such as centering or checking clearances are not required. Wear parts can be replaced individually, providing a cost-effective design.

| Max. discharge capacity range | 400 – 1400 / 500 – 1400 L/min |

|---|---|

| Max. head range | 14 – 45 / 22 – 62 m |

| Main materials | CFRPP |

| Required power range | 3.7 – 18.5 kWNote |

| Discharge bore | 32A, 40A, 50A, 65A |

| Liquid temperature range | 0 – 80°C |

| Sealing method | Seal-less construction |

• Note: 60Hz only

Kindly use this inquiry form for placing an order or sending your inquiry

about our fluid control devices including chemical pumps.

HomeP