Product information

- Catalogs and Download

- Product data, catalogs, and instruction manuals can be downloaded from the member site.

※ Membership registration is required.

Max. discharge capacity range (50/60Hz): 170 – 600 / 100 – 600 L/min Excellent corrosion resistance, durability, and safety

※In order to download information materials and catalogues, you need to register a user

account (for free) with us. Membership Registration

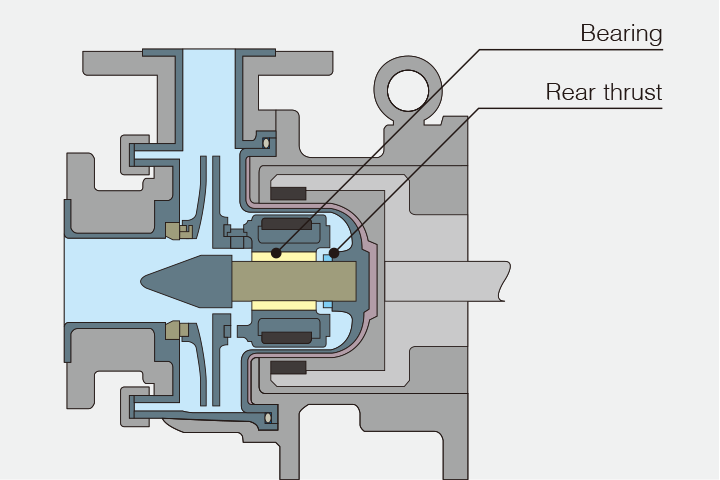

The proven non-contact system and self-radiating bearing structure deliver substantial improvements in tolerance of dry running and poor suction conditions.

Unlike conventional magnetic drive pumps, the MXM series are designed to prevent contact between the bearing and the rear thrust faces, even during dry running. By preventing contact, the rear thrust ring minimizes heat generation to prevent melting of plastic parts.

Through heat-dispersion holes provided in the fixed portions of the impeller and the magnet capsule, the liquid around the spindle and the bearing is forced to circulate so that heat generated by sliding can be reduced effectively. Thus, thermal deformation and melt are prevented.

The MXM series employ optimum anti-corrosive materials such as carbon fiber reinforced ETFE (CFRETFE), high quality ceramic and carbon for parts that come in contact with liquid. The most suitable impeller size and motor output can be selected for the required liquid property.

The pumps have an external armour of high strength ductile cast iron for use in heavy duty chemical process applications. The sealing performance between the front casing and the rear casing is drastically enhanced by our original structure, offering high reliability.

The MXM features a unique rear casing shape designed to prevent stress concentration. This increases both the pump’s pressure resistance and the mechanical strength of the spindle support. The high temperature model uses a dual structure incorporating an FRP rear casing cover. In addition to further increasing the pump’s pressure resistance, it improves safety with dual containment preventing liquid leakage in the event of unexpected damage to the rear casing.

| Max. discharge capacity range | 170 – 600 / 100 – 600 L/min |

|---|---|

| Max. head range | 5.5 – 29 / 7.5 – 42 m |

| Main materials | CFRETFE |

| Required power range | 0.4 – 3.7 kW |

| Discharge bore | 25 A, 40 A |

| Liquid temperature range | −10 – 105°C (Please contact us for details.) |

| Sealing method | Seal-less construction |

Video

Kindly use this inquiry form for placing an order or sending your inquiry

about our fluid control devices including chemical pumps.

HomeP