Product information

- Catalogs and Download

- Product data, catalogs, and instruction manuals can be downloaded from the member site.

※ Membership registration is required.

Max. discharge capacity range (50/60Hz): 90 – 800 / 100 – 800 L/min Magnetic drive pump resistant to abnormal operations

※In order to download information materials and catalogues, you need to register a user

account (for free) with us. Membership Registration

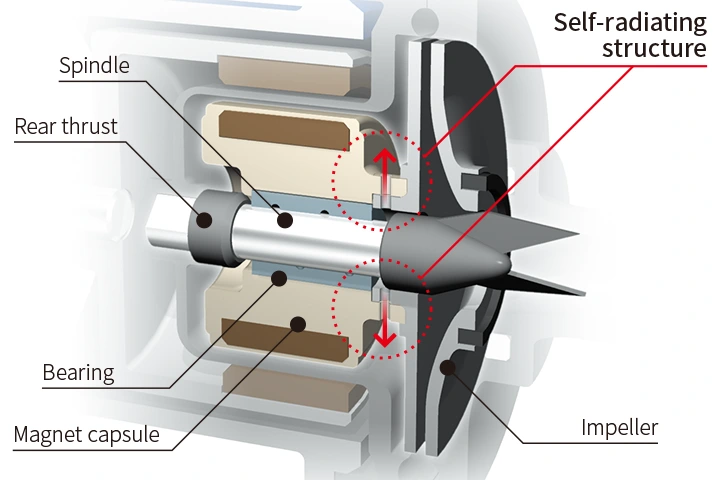

Through heat-dispersion holes provided in the fixed portions of the impeller and the magnet capsule, liquid is circulated under pressure between the spindle and bearing to reduce friction heat transmission and prevent thermal deformation. (Except MX-70, 100)

New for this series or size – can be rotated to match the end users piping alignment with ease. (Except MX-70, 100)

All stress bearing portions, such as the front and rear casings, are reinforced by means of ribs to improve the pressure resistance and the mechanical strength of the pump. The bearing is not only fixed by conventional press fit but is also sandwiched between the abutting portion in the depth of the magnet capsule and the rear end of the impeller to improve its reliability under high temperature. (Except MX-70, 100) MX-402(H), 403(H) and 505 models: an unplugging preventive lock pin is adopted for ensuring more steady securing.

The drive magnet and driven magnet are carefully positioned so that their strong magnetic field limits rear thrust contact of the magnet capsule parts, even during dry running. As a result, heat generation is greatly reduced and liquid circulation is maintained. (Except MX-70, 100)

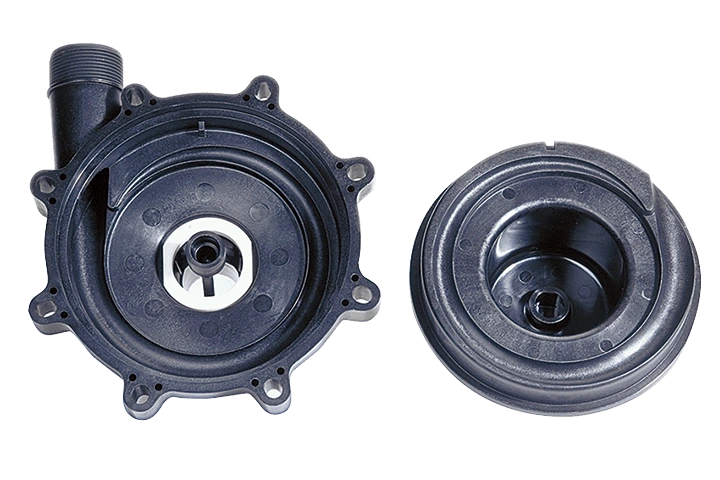

The MX series is the first resin magnet pump which uses the pump casing divided into the front casing and the rear casing to form a vortex chamber as an ideal form. Therefore, internal leakage is kept to a minimum and overall hydraulic efficiency is enhanced. (Except MX-70, 400, 505)

Lineup of MX-505 with dramatically improved suction characteristics and pump efficiency, while maintaining the original durable structure.

| Max. discharge capacity range | 90 – 800 / 100 – 800 L/min |

|---|---|

| Max. head range | 8 – 35 / 11 – 37 m |

| Main materials | GFRPP |

| Required power range | 0.15 – 3.7 kW |

| Discharge bore | G 1, 25 – 50 A |

| Liquid temperature range | 0 – 80°C (10 – 80°C for Aflas® O ring.) |

| Specific gravity limit | Up to approx. 1.2 (Please contact us for details.) |

| Sealing method | Seal-less construction |

Video

Kindly use this inquiry form for placing an order or sending your inquiry

about our fluid control devices including chemical pumps.

HomeP