Product information

- Catalogs and Download

- Product data, catalogs, and instruction manuals can be downloaded from the member site.

※ Membership registration is required.

Max. discharge capacity range(50/60Hz): 90 – 440 / 85 – 520 L/min Versatile self-priming magnetic drive pump with enhanced durability under abnormal operation

※In order to download information materials and catalogues, you need to register a user

account (for free) with us. Membership Registration

The SMX has a modular structure to handle liquids with high specific gravities. Use of standard motors extends the range of liquid application.

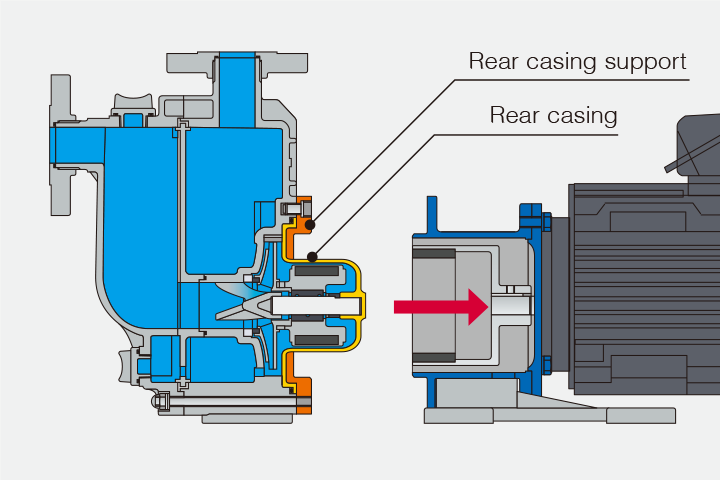

The pump wet end can be removed from the motor as a complete assembly without dismantling, thanks to an additional rear casing support. The pump wet end comprises the minimum number of parts for easy maintenance.

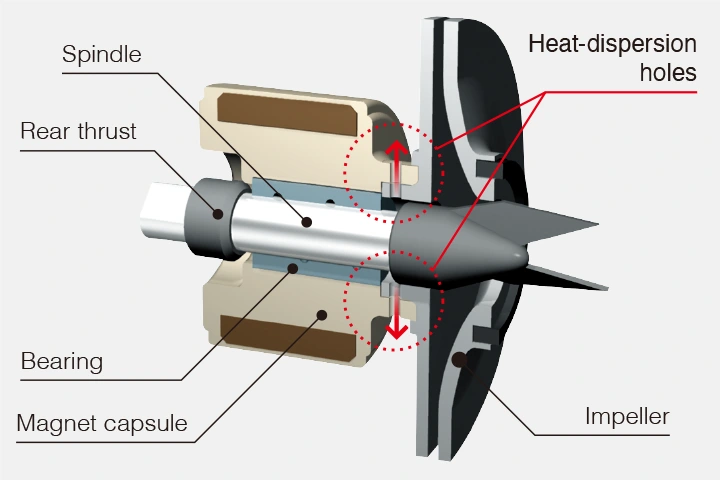

Our original self-radiation structure efficiently disperses bearing friction heat to protect the pump under abnormal operating conditions. In addition, our non-contact structure prevents contact between rear thrust face and bearing, to eliminate heat buildup during dry running.

The SMX requires no external self-priming chambers or valves. The gas-liquid separation design ensures fast self-priming. An exceptional self-priming duration of up to 4m in only 90 seconds is now possible.

| Max. discharge capacity range | 90 – 440 / 85 – 520 L/min |

|---|---|

| Max. head range | 13 – 25.5 / 11.5 – 37.5 m |

| Main materials | GFRPP |

| Required power range | 0.4 – 3.7 kW |

| Discharge bore | 25A, 40A |

| Liquid temperature range | 0 – 80°C |

| Sealing method | Seal-less construction |

Video

Kindly use this inquiry form for placing an order or sending your inquiry

about our fluid control devices including chemical pumps.

HomeP