Product information

- Catalogs and Download

- Product data, catalogs, and instruction manuals can be downloaded from the member site.

※ Membership registration is required.

Max. discharge capacity range (50/60Hz): 35.2 / 42.5 L/min

No Liquid Leaks

Ideal for Handling Chemical Liquids

※In order to download information materials and catalogues, you need to register a user

account (for free) with us. Membership Registration

Fine ceramic gears provide superior abrasion resistance and chemical resistance than conventional gear pumps, prevent “galling” and “seizing” when the pump operates at a high speed. Main materials are stainless which provides corrosion resistance and thermal resistance. Superior anticorrosive materials such as stainless, ceramic, PTFE and carbon are used in liquid ends so that all sorts of chemical liquids can be handled.

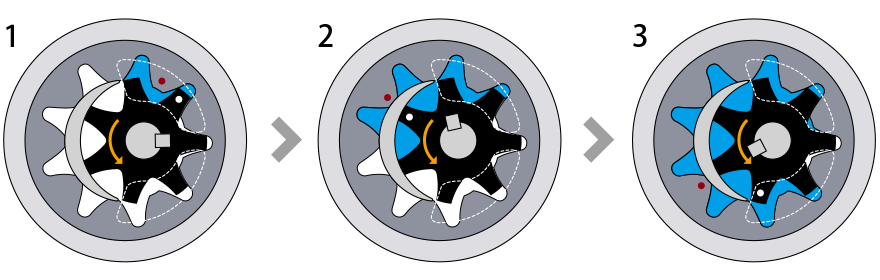

Without the pulsation that is common to the reciprocating pump and the gear pump for general uses, liquid is transferred quietly and smoothly , not agitating or generating foam/bubbles.

Magnetic drive seal-less pumps are free from leakage problems and the need for seal replacement.

Performance has been noticeably improved. Ceramic gears make it possible to reduce spaces between parts, therefore outperforming conventional metal gear models. The pump is far less subject to declining output even under high pressure.

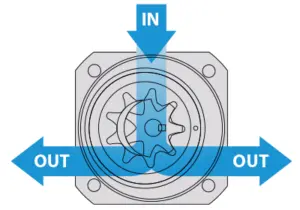

Because the suction port is at the top of the pump, the pump chamber is filled with liquid when pump stops. The self-priming capacity is enhanced at re-start.

• The height of self-priming varies depending on the liquid characteristics, liquid temperature, piping conditions. Please contact us for details.

By simply combining a PFC controller, magnetic flowmeter, inverter, and back pressure valve, it is possible to inject a constant flow with less pulsation even if there are fluctuations in the level of the suction tank or load fluctuations on the discharge side.

Regardless of the temperature change, viscous liquid can be handled at accurate flow rate, which cannot do with other pumps. As the output is linearly related to rpm, the flow rate is easily controlled by changing motor speed. The pump achieves fixed injection with the rangeability 10 times greater than conventional metering pumps.

• Rangeability 1:100

• To perform constant flow Injection, use this pump with a PFC controller, magnetic flowmeter, inverter and back pressure valve.

Fine ceramics have excellent abrasion resistance so there is almost no wear on the parts and they can be used for a long period. In addition, the pump performs pulsation-free operation without pulsation suppression accessories such as air chambers. Compared to reciprocating pumps, fewer components reduce initial and total costs.

We provide comprehensive support for our products according to your needs, from designing and manufacturing piping units and control panels to inspection, shipping, and on-site adjustment.

The discharge port is on the right side when viewed from the front of the pump, also available selected the left side as a special order.

| Max. discharge capacity | 35.2 / 42.5 L/min |

| Max. discharge pressure*1 | 0.7 MPa |

| Max. speed | 1800 min-1 |

| Main materials | SUS316, SiC, PTFE |

| Motor output range | 0.2 – 3.7kW |

| Liquid temperature range | 0 – 80℃ |

| Viscous liquid*2 | 0.5 – 1000 mPa·s |

| Slurry liquid | Please contact us for details. |

| Sealing method | Seal-less construction |

*1 The max. value depends on the motor speed and liquid viscosity. Please contact us for details.

*2 Please contact us for the motor speed and motor output suited to the viscosity of your liquid.

Kindly use this inquiry form for placing an order or sending your inquiry

about our fluid control devices including chemical pumps.

HomeP