Product information

- Catalogs and Download

- Product data, catalogs, and instruction manuals can be downloaded from the member site.

※ Membership registration is required.

Preventing clogging and sticking with valveless construction

※In order to download information materials and catalogues, you need to register a user

account (for free) with us. Membership Registration

Capable of ultra-high precision dosing at a micro discharge capacity. Simple adjustment of the discharge capacity by changing the angle of the pump head.

Ceramics and PTFE resins are used on the wetted surface, lending greater resistance when pumping acid, alkaline, organic solvents, and other liquids.

The unique valveless structure enables the smooth metering transfer of high viscous liquid at a maximum of 20,000 mPa·s.

* The handling of viscous liquid is limited to the motor type with a speed reducer.

The compact and light, making them ideal for built-in applications. The reversible motor direction allows you to reverse the flow without needing to change the piping.

Because there are no suction/discharge valves, the pump is able to discharge directly into a vacuum (negative pressure) without the need for electromagnetic valves. Maintains a constant flow even if the suction/discharge pressure fluctuates.

* Accuracy of injection into vacuum may vary depending on piping conditions.

This pump enables air to be automatically discharged from the outlet, thereby preventing problems caused by gas lock.

* Depending on the installation conditions or the liquid being handled, there are times gas cannot be discharged smoothly. Contact us for more details.

Hi-Cera pump V-25 is a high-capacity pump with an injection volume that is 3.8 times that of the conventional model (V-15). The unique valveless structure of Hi-Cera pumps and stepper motors enable highly accurate injection with excellent controllability. Coupling connection type that can be connected to motors other than stepper motors is also available.

To adjust the dispense volume, precise stroke adjustment is possible by adjusting the swing angle of the pump head with the rotary knob as desired. Stepper motor type is high-precision injection with excellent controllability.

By complying with European EN standards, CE marking is now available as standard. The coupling connection type complies with the Machinery Directive without the motor installed.

The flushing port reduces the plunger lock caused by adhesive or crystallization of the fluid used.

The pump head design is ease for maintenance because of its simple structure with fewer parts. Pump head is also disassemble easily.

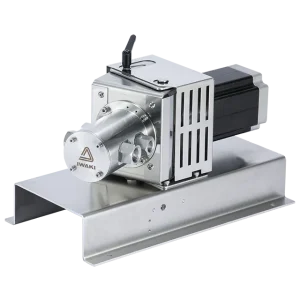

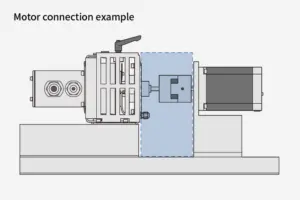

Coupling connection type V-25-N can be used by connecting a prepared motor with a coupling.

* It is necessary to select a motor by referring to the recommended values of motor torque described in the product specifications and instruction manual.

* This product does not come with connecting parts such as motors and couplings, and covers for rotating parts. Prepare them.

* A cover must be added to the rotating parts before operation. Be sure to prepare them and install them before operation. (Blue part in right figure)

| Max. discharge capacity | 1400/1682 mL/min |

|---|---|

| Max. discharge pressure | 0.7 MPa |

| Main materials | Al2O3, SiC, SUS316 |

| Required power range | 15 – 40W |

| Liquid temperature | 0 – 40℃ |

| Viscous liquid | 20000 mPa·s (depending on model) |

| Slurry liquid | Please contact us for details. |

| Seal method | Lip seal |

| Pump | Max. discharge capacity per shot | 11 mL/shot |

|---|---|---|

| Max. discharge capacity per min (RV) | 3300 mL/min | |

| Max. motor speed | 300 min−1 | |

| Max. discharge pressure | 0.2 MPa | |

| Stepper motor | Type | 2-phase bipolar |

| Basic step angle | 1.8° | |

| Power voltage | 48 VDC±1V | |

| Insulation class | B | |

| Photo micro sensor | Power voltage Vcc | 5 – 24 DCV |

| Output open-circuit voltage Vo | Vcc V | |

| Output inflow current Isink | 50 mA |

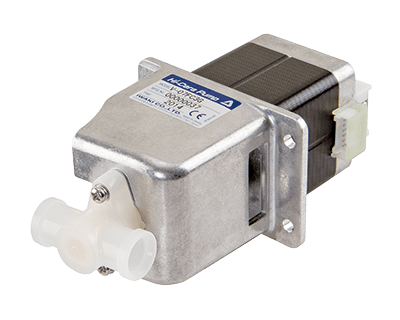

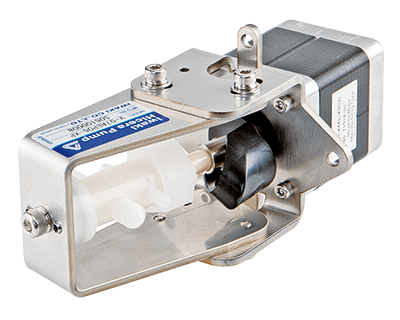

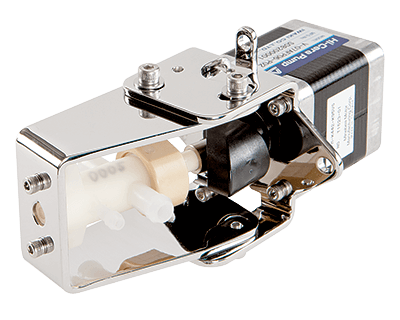

The compact and lightweight V-05 / 07 series is a compact plunger pump that is ideal for incorporating into equipment. Since it is driven by a DC motor, highly accurate discharge rate control is possible. It has a variable discharge rate function and a flushing port can be selected, so it is possible to inject chemicals cleanly. Since there are a wide variety of fittings, it can be incorporated into various devices.

Long life design, Low power consumption, lightweight

V-07AF4 is a long-life design with a design life of 95,000 hours. (Conventional type “V-07AF3”: 90,000 hours)

Features a lightweight design utilizing an aluminum die cast frame, and includes a lock-type connector on the motor and sensor.

High corrosion resistance

PVDF or ECTFE is used for the pump head material. Supports the transfer of strong alkaline.

High-temperature capability

Can be cleaned with water as hot as 95˚C.

| Model | V-07AF4 | V-05ZF(P)66-P | V-07AEP06-P | V-07AF(P)66-P | V-07AFP06-P |

|---|---|---|---|---|---|

| Volume/shot mL |

0.1 | 0.1 | 0.1, 0.2, 0.3 | 0.1, 0.2, 0.3 | 0.1, 0.2 |

| Flow range mL/min |

1 – 20 | 0.5 – 30 | 0.5 – 90 | 0.5 – 90 | 0.5 – 60 |

| Rotation speed min-1 |

10 – 200 | 10 – 300 | 10 – 300 | 5 – 300 | 5 – 300 |

| Max. discharge pressure kPa |

40 | 150 | 150 | 150 | 200 |

Kindly use this inquiry form for placing an order or sending your inquiry

about our fluid control devices including chemical pumps.

HomeP