Product information

- Catalogs and Download

- Product data, catalogs, and instruction manuals can be downloaded from the member site.

※ Membership registration is required.

Solve water treatment issues with outstanding control

※In order to download information materials and catalogues, you need to register a user

account (for free) with us. Membership Registration

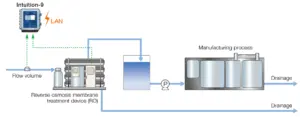

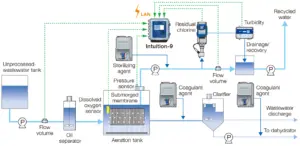

Intuition-9 is the top-of-the-line model of water treatment controllers, integrating high-performance sensor functions, measuring instruments, liquid processing, and various data communication technologies into a single unit.

Its proven performance stands at the highest level in the water treatment industry. It achieves intuitive operability through an easy-to-setup large touch panel display and swipe functionality.

Management systems can be configured for multiple cooling towers, boilers, closed-loop systems, and all water treatment-related processes.

It monitors and manages based on inputs from various water quality sensors and measurements from field devices that measure corrosion rate, level, temperature, pressure, and more. Operating 24/7, 365 days a year, it notifies both on-site personnel and remote staff about system performance status.

Furthermore, using Intuition-9 enables comprehensive management with high reliability, not limited to water treatment alone.

Centralized management of independent equipment and remote data logging, etc.

| Model (Example) |

WCT93000HAACGNNN-NNNNNN | For cooling |

|---|---|---|

| WIN94000HAACGNNN-NNNNNN | For general control | |

| WIN97000HDDDDDNN-NNNNNN | For monitoring | |

| Applicable sensor (sold separately) | Electrode type conductivity sensor ESB type | |

| Electromagnetic conductivity sensor MCS type (for cooling and general control only) | ||

| pH sensor WEL type (SH type require a separate preamplifier) | ||

| ORP sensor WEL type (SR type require a separate preamplifier) | ||

| Measurement | Two-electrode conductivity | Measurement range: 0.000 to 30.000 mS / m (cell constant 0.01), 0.00 to 300.00 mS / m (cell constant 0.1), 0.0 to 3000.0 mS / m (cell constant 1), 0 to 30000 mSm (cell constant 10) |

| Linearity: F.S±1% (per controller) | ||

| Electro- magnetic conductivity (Measurement range selection) | Measurement range: 50.0 to 1200.0 mS / m, 300.0 to 4000.0 mS / m, 1000 to 15000 mS / m, 5000 to 50000 mS / m, 20000 to 200,000 mS / m (optional) (Display starts from 0) | |

| Linearity: F.S±1% (per controller) | ||

| pH | Measuring range: 0.00 to 14.00 pH | |

| Repeatability: ±0.05 pH (per controller) | ||

| ORP | Measuring range: ±1,500.0 mV | |

| Repeatability: ±5 mV (per controller) | ||

| Temperature | Measuring range: −5.0 – 260.0°C, Linearity: F.S±1% (per controller) Unit: °C | |

| Cumulative flow into a low-speed flowmeter | Maximum frequency: 20Hz, minimum 25msec, Meter coefficient: 1 to 100000 units / 1 pulse, Flow unit: lit, m3 | |

| Cumulative flow, Instant flow into a high-speed flowmeter | Max frequency: 500 Hz, minimum pulse width 1.00msec, Pulse constant: 0.01 to 100,000.00 pulse/lit, m3 Flow unit: lit, m3 Time unit: /sec, /min, /hour, /day | |

| Cumulative flow, Instant flow into a flow checker | Meter factor: 0.001 to 1000.000 Unit: mL, Flow unit: lit, m3 Time unit: /min, /hour, /day | |

| Display | Touch panel LCD | 7inch color LCD (1024 x 600), Capacitive |

| Input | SensorNote1 | 2 Electrode/Electromagnetic type conductivity sensor, pH/ORP sensor, Corrosion sensor |

| Temperature | Pt 100, Pt 1,000 (freely selectable), automatic temperature compensation | |

| AnalogNote1 | DC4-20mA maximum 24 points, input resistance CH1: 130Ω, CH2 to 6: 280Ω DC24V built-in, isolated, total 2W, However, the total power consumption for all channels on the I/O board (up to 6 inputs) is 9W, Compatible with 2-wire loop, 2-wire with power supply, 3-wire, and 4-wire systems | |

| External | ×12, No-voltage contact signal, 12V 2.3mA, Interlock, low-speed flow meter, high-speed flow meter, flow checker | |

| Output | RelayNote2 | ×8 or 0 to 12, Voltageed contacts Power supply voltage output, with fuse Total current less than 6A Non-voltage contact 6A (Resistive load) Semiconductor contact (Pulse output) Maximum load DC40V, 0.2A |

| AnalogNote1 | DC4 to 20 mA, Maximum 16 points, isolated type, maximum load resistance 600Ω | |

| Power supply voltage | 1Ø 100-240 VAC, 50 or 60Hz, 15A (20A) | |

Note1 : The number of sensor inputs and analog inputs/outputs is determined by the I/O module speci fication symbol.

Note2 : The contact type and number of relay outputs are determined by the relay module specification symbol.

pH • ORP sensor

• Internal liquid replenishment type.

• Less clogging at the liquid junction and long life.

• It is ideal for process applications such as waste water treatment and surface treatment.

• pH/ORP sensor for high cost-performance.

• The electrode part is easy maintenance.

• In the housing has a built-in battery-less preamplifier, can be directly connected to the Intuition-6 · Intuition-9.

Conductivity sensor

• Measurement range*: 0.0 to 3000.0mS/m, 0.00 to 300.00mS/m, 0.000 to 30. 000mS/m

• Operating temperature: 5 to 45°C

• Temperature sensor: Pt1000 Ω

*Indicates the range when used with the W100 series or Intuition-6 series; these are not the performance of a stand-alone sensor itself.

• Measurement range: 0 to 200 S/m

• Operating temperature: 0 to 60°C*

• Temperature sensor: Pt1000 Ω

*This varies depending on the types and concentrations of liquid used.

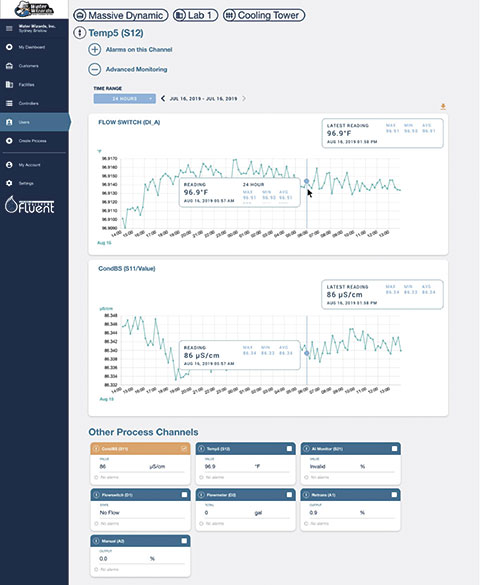

Easy to set up and use, Walchem Fluent incorporates IoT, process automation, remote monitoring and control, and data graphing capabilities to harness your capabilities efficiently and effectively. Walchem Fluent will be one of the most valuable resources for managing water treatment services. Compatible models: Intuition-6, Intuition-9

Fluent uses https to provide information. Since https encrypts and provides data so that it cannot be viewed or tampered with by a third party, users can view the data with peace of mind.

The dashboard is a function that extracts and displays the customers, facilities, and their parameters that are being watched. For the alarm, you can select the display of “All / Confirmed / Confirmed”. Also easily can be monitored with a ☆ to customers and facilities required monitoring.

Escalation is a function that notifies alarm notifications (emails) to groups that are divided in stages by email. Prevents unprocessed troubles.

Kindly use this inquiry form for placing an order or sending your inquiry

about our fluid control devices including chemical pumps.

HomeP