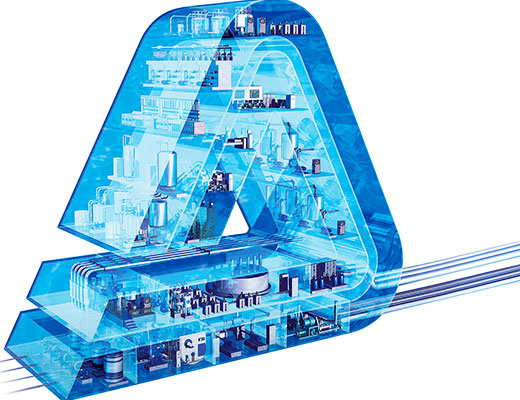

ISO9001 and ISO14001 based control system

We received ISO9001 certification in 1996. We have rigorous standards in place and continuously optimize and streamline core design and production processes for quality improvement.

We received ISO14001 certification in 2005 and have many measures to minimise our environmental impact.